ROLLING STEEL

ROLLING STEEL

Full Duty Non-Insulated Service Doors 6000

6000 Series Non-Insulated Models: 6180 – 6181 – 6200 – 6201 – 6220 – 6221 – 6244 – 6266

The Series 6000 roll-up garage doors are engineered and designed for maximum strength and durability. Available in both insulated and non-insulated, the Series 6000 line is an industrial product built without shortcuts to provide a high degree of confidence for specifiers and end users. The rolling non-insulated service doors are available in a host of slat profiles, gauges, and color options for design flexibility and to meet the rigorous applications for use.

OVERVIEW

Rolling Steel non-insulated doors are available in a variety of gauges, insulation and options to achieve your project requirements.

Non-Insulated Models: Gauge & Slat Profile

- 6180: 18 gauge/Curved Slat

- 6181: 18 gauge/Flat Slat

- 6200: 20 gauge/Curved Slat

- 6201: 20 gauge/Flat Slat

- 6220: 22 gauge/Curved Slat

- 6221: 22 gauge/Flat Slat

- 6244: Aluminum/Flat Slat

- 6266: 22 gauge Stainless Steel/Flat

Operation: Manual push-up, chain hoist (standard) or motor operation

Available Standard Colors:

- Gray, White, or Galvanized for models 6180, 6181, 6200 and 6201

- Gray, White, Tan, Brown, or Galvanized for models 6220, 6221

- Clear Anodized for model 6244

- #4 finish for model 6266

Powder coat: 188 RAL powder coat color options*

*not available for models 6244 and 6266

Half-hexagonal formed hoods deliver superior structural rigidity and aesthetic appeal

Options and accessories available

CURTAIN

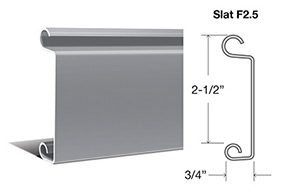

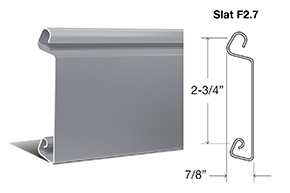

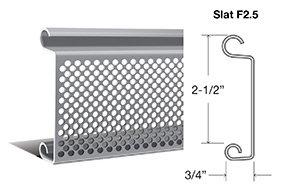

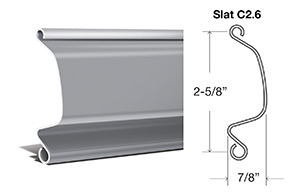

SLAT PROFILE:

F2.5 Flat Slat Detail

Models 6181,6201, 6221

F2.7 Flat Slat Detail

Models 6244, 6266

F2.5 Perforated Flat Slat Detail

Optional for model 6201

Flat Slat Curtain- Exterior Detail

C2.6 Curved Slat Detail

Models 6180, 6200, 6220

Curved Slat Curtain- Exterior Detail

GAUGE & MAXIMUM SIZE:

- 6180: 18 gauge/Curved Slat, 30’0″ max std. width / 28’0″ max std. height

- 6181: 18 gauge/Flat Slat, 30’0″ max std. width / 28’0″ max std. height

- 6200: 20 gauge/Curved Slat. 28’4″ max std. width / 28’0″ max std. height

- 6201: 20 gauge/Flat Slat, 28’4″ max std. width / 28’0″ max std. height

- 6220: 22 gauge/Curved Slat, 20’4″ max std. width / 20’4″ max std. height

- 6221: 22 gauge/Flat Slat, 20’4″ max std. width / 20’4″ max std. height

- 6244: Aluminum/Flat Slat, 14’4″ max std. width / 18’4″ max std. height

- 6226: 22 gauge Stainless Steel/Flat, 18’4″ max std. width / 20’4″ max std. height

COLOR/FINISH:

White Exterior

Gray Exterior

Galvanized Exterior

Tan Exterior

Brown Exterior

Stainless Steel with #4 finish

Aluminum curtain with clear anodized finish

ENDLOCKS & WINDLOCKS:

- Malleable, zinc-placted cast iron endlocks and windlocks maintain curtain alignment and increase windload capacity. Galvanized malleable cast endlocks are fastened to every other slat. Windlocks are added as dictated by door size & windload requirement.

- Windload: Designed to withstand a minimum of 20 lbs psf (per sq feet) of windload to an amount that prevents curtain per square foot of windload deflection to prevent buckling or being blown out of the guides.

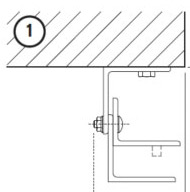

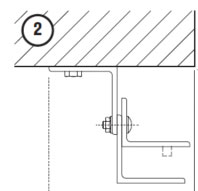

HOOD

HALF-HEXAGONAL FORMED HOOD :

- Fabricated from minimum 24 gauge galvanized steel sheet shaped to fit within the headplates.

- Unique half-hexagonal shape is more rigid and easier to handle and install than more traditional round hoods

- Intermediate hood support(s) furnished as required.

- Available in colors/finishes to match curtain.

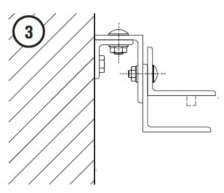

OPERATION

Available with Chain-hoist (standard), Manual Push-up and Motor Operation

Chain-hoist operation

(comes standard)

Motor Operation

Motor Operation

MOTOR OPERATION:

- Available in 1/3 to 5 HP as required; single- or three-phase available

- Refer to the motor operator area chart to select operator type based on dimensions and gauge

- Choose between wall mount or front of headplate mount. Use the charts to determine headroom, sideroom and backroom clearance requirements.

SPRINGS:

- Spring tension assembly within barrel by precision ball bearings.

- Assembly designed for 20,000 cycle life springs (Standard). Higher cycles optional

Counterbalance